myamo

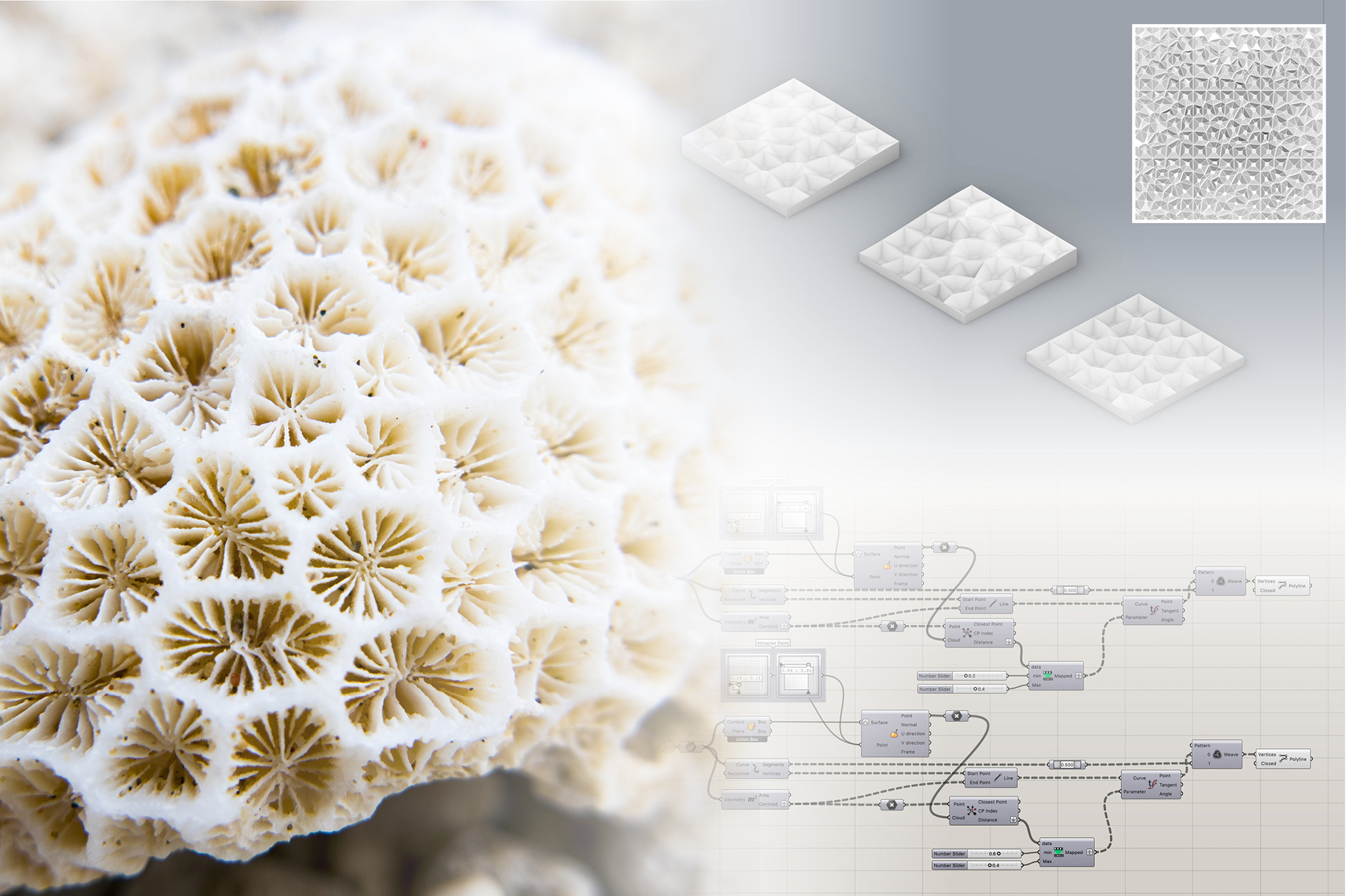

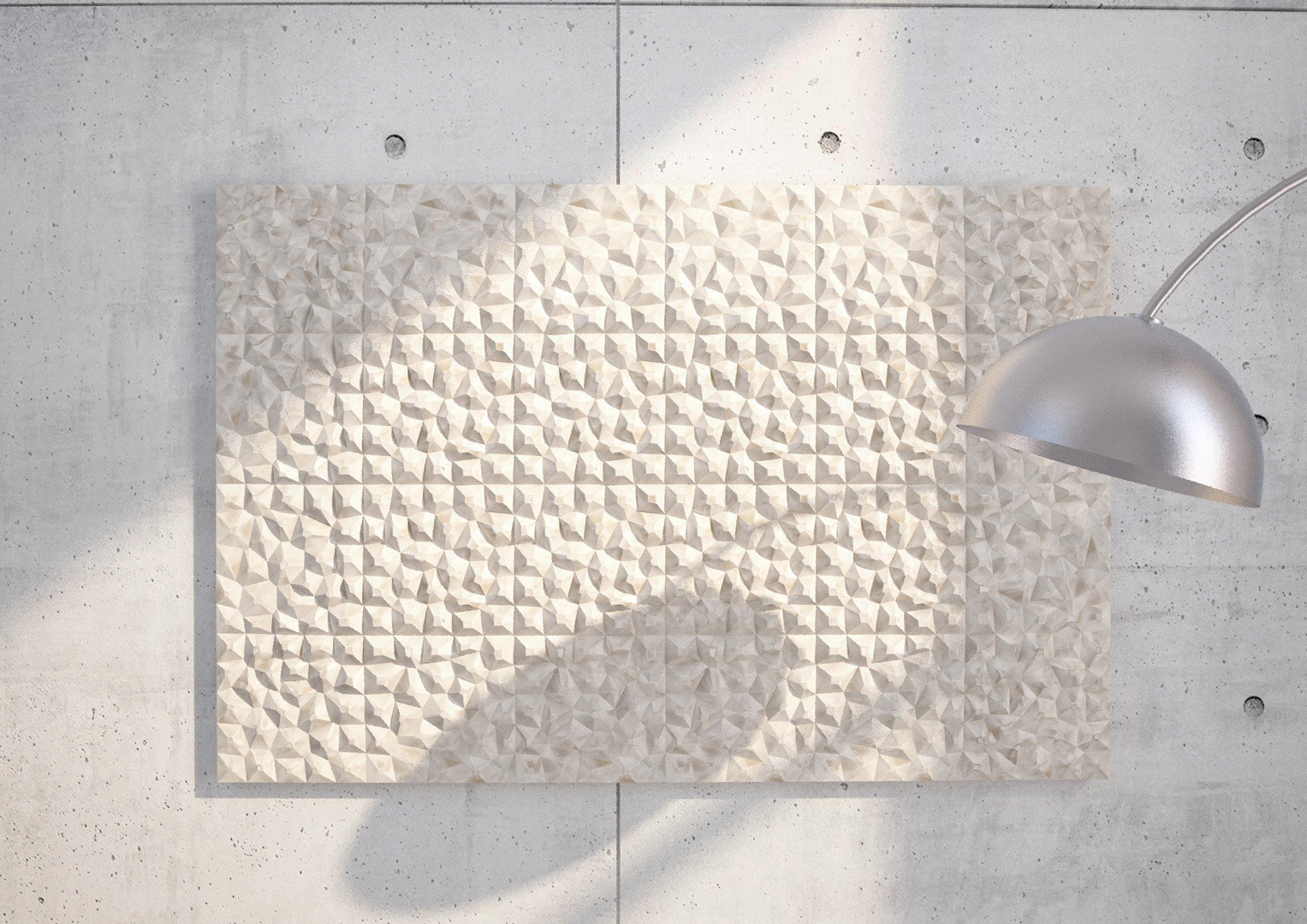

Myamo are modular acoustic absorbing wall panels out of fungi-based material. Inspired by cell structures in nature, the characterized parametric design brings acoustic functions, aesthetics, and sustainability into harmony.

mycelium, fungi-based material

Mycelium-Material is a sustainable composite composed of agricultural by-products such as straw or wood and mycelium, the root network of fungi. Unlike conventional materials, the manufacturing process is characterized by a growing process, in which the mycelium breaks down organic matter by absorbing nutrients and spreading into roots, performing as a binding glue.

aesthetics

The aim was to find a design which is in harmony with the organic imperfect surface of the mycelium-materials. The final design was developed in 3D-Software and is inspired by a voronoi-diagram, which can be found in nature.

ideation

The modular system is composed by a combination of three tiles that can be adjusted and rotated to compose a complex geometry where the heights and textures vary through the surface. This allows an individually expandable design and the creation of a relief-like overall picture.

manufacturing & moulding

After generating the three-dimensional pattern the lid of the moulds have been manufactured by a CNC milling machine and a connected system for the base was realised. After manufacturing the material, it was given into the previously sterilised moulds and the growth process below room temperature and low exposure to light was initiated. During the moulding process, it was important to disinfect everything to exclude possible germs and mould. After 15 days, the material was removed and dried.

awards

exhibitions

2021 | Deutsches Sport & Olympia Museum Köln | MehrWert NRW

2020 | RWTH Aachen | Ecological material mini library

2020 | RWTH Aachen | BUILDING PRODUCTS in the cycle

2020 | MAK Köln | Ökorausch Festival

2019 | MAK Köln | Kölner Design Preis

published in

03/2021 | Ganz natürlich | AW Architektur & Wohnen

02/2021 | Zukunftsmaterial | COUCH Magazin

01/2021 | Pilze, ein Material der Zukunft? | www.swiss-architects.com

01/2021 | Akustisch wirksam | www.german-architects.com

Would like to learn more about myamo and its manufacturing process?